Bombora is meeting energy transition demands with a market disruptive product to deliver continuous, reliable ocean energy for global use in national and island grids.

Bombora is meeting energy transition demands with a market disruptive product to deliver continuous, reliable ocean energy for global use in national and island grids.

Bombora has developed a patented membrane-style wave energy converter, mWave™. mWave™ is unique among wave energy converters as it simultaneously addresses the cost of energy and ocean wave survivability challenges. This new approach proffers a new era for wave energy.

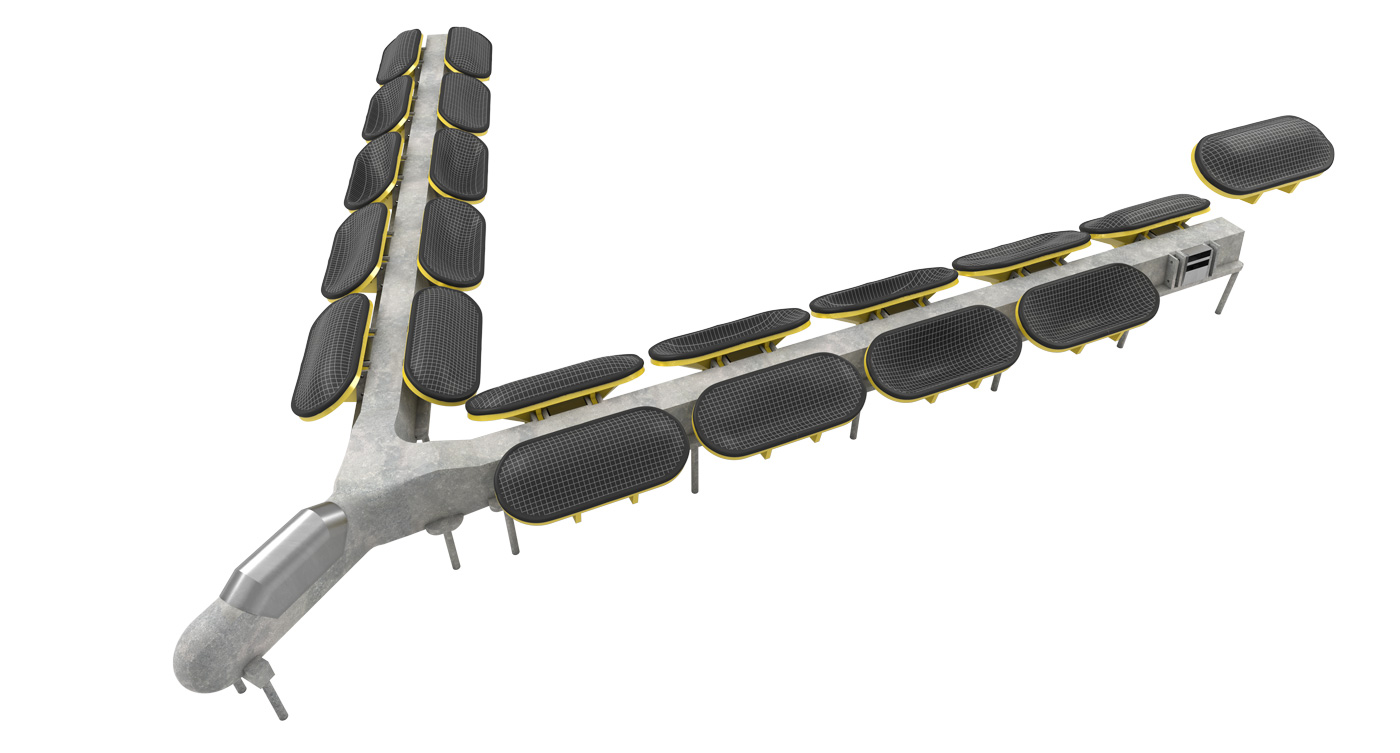

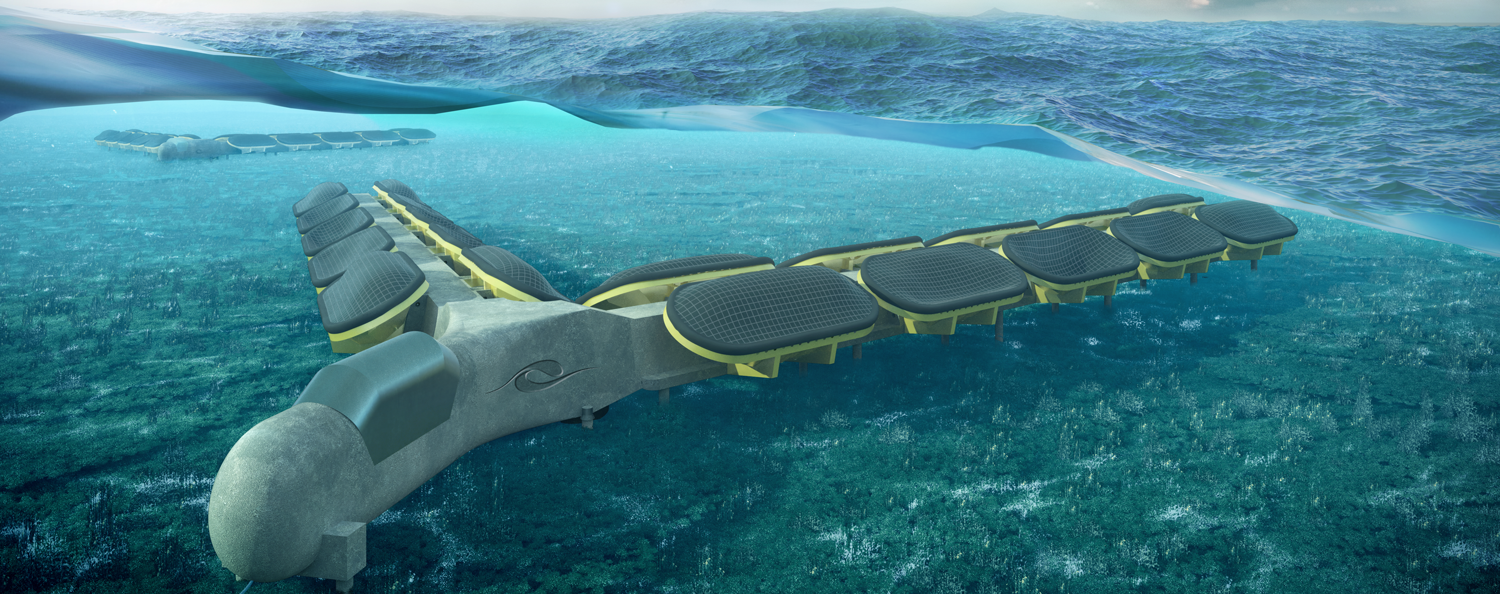

mWave™ features a series of air-inflated rubber membrane covered concave cells mounted to a structure below the ocean’s surface creating an air-filled volume. To maximise energy capture, the structure is arranged at an angle to the incoming waves. As waves pass overhead, air is pushed out of each cell through a series of valves into a one-way air-duct . The cells are refilled once the wave has passed. The flexible membrane is made from industrial grade rubber. The longstanding use of similar materials in a range of marine applications has demonstrated the material’s reliability and longevity.

mWave™ has no external parts, other than the flexible rubber membranes. Our robust rubber cell membrane extracts power simply without complex mechanisms greatly reducing maintenance requirements. Our replaceable modular design streamlines maintenance, minimising downtime and maximising power output.

mWave™’s cell modules have the unique ability to shut down in extreme storm events. Limiting the loads reduces capital costs and improves the all important cost of electricity.

The air flow in the duct drives an unidirectional flow turbine which in turns drives a variable-speed generator. This type of turbine and generator are off-the shelf technology, even if adapted for the mWave™ operating envelope.

Electricity from the generator is transferred to the shore via a sub-sea cable. Following a process of power conditioning, the electricity is delivered into the local grid.

All operations and maintenance are achievable using existing service vessels used in both fixed bottom wind and offshore oil and gas industries.

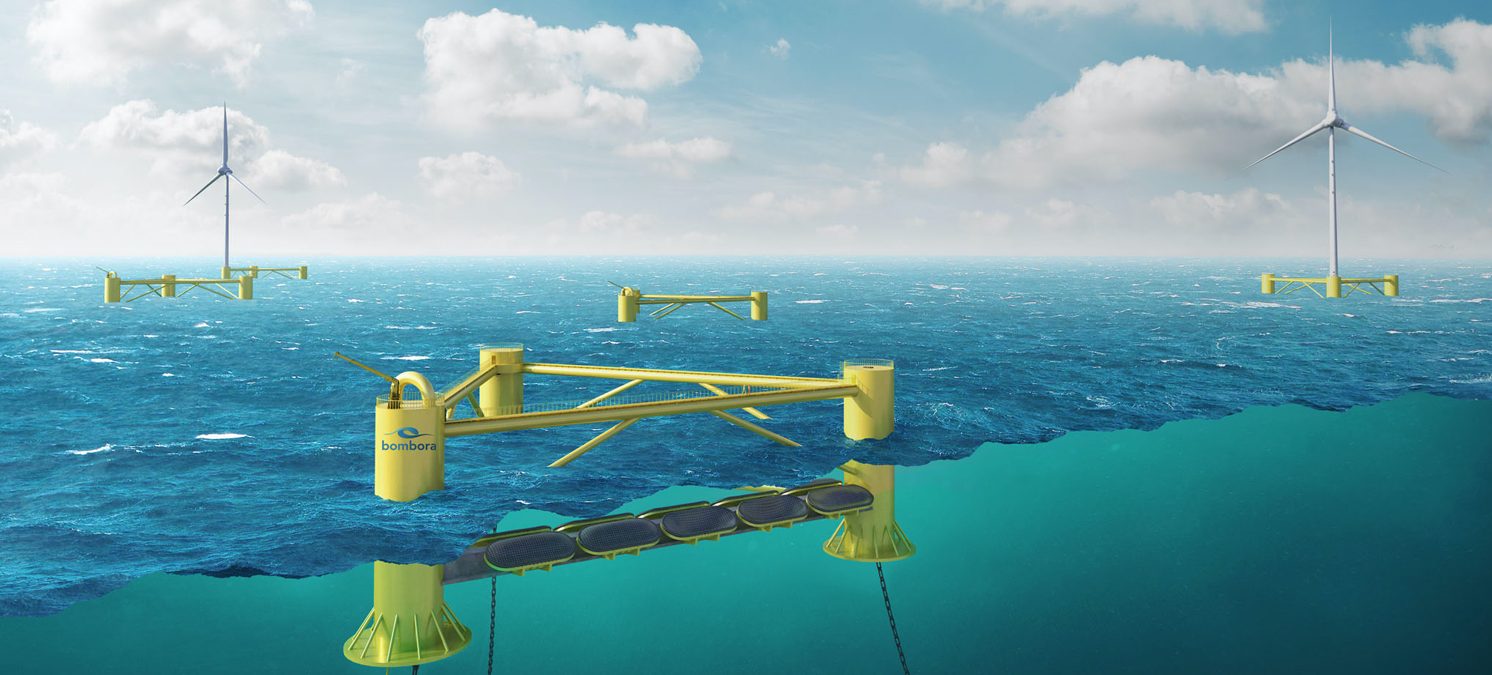

mWave™ can be deployed on different platforms to suit a nearshore or offshore ocean environment. Find out more about Bombora’s Fixed mWave™ , Floating mWave™ and Integrated mWave™ platforms here.

Data from scaled testing is crucial for engineering, optimisation, modelling and certification.

mWave has been through a rigorous and continuous, test and validation program since 2012, resulting in structural, process and cost efficiency improvements. mWave’s competitive cost of energy model, combined with its power rating and robust, scalable features, unite to provide confidence in the staged technology development approach and Bombora’s capability to deliver a market disruptive commercial product.

Scaling mWave to 3 MW and 4MW, respectively for bottom-fixed and floating platforms, significantly reduces the equipment CAPEX cost per MW. The modular design of mWave cells and PTO allows scale manufacturing processes to be employed, further improving project CAPEX.

Bottom-fixed mWave can be floated to site using small low-cost vessels for project deployment, whilst the modular design of the cells and PTO allow the key operating components to be exchanged offshore for convenient maintenance onshore driving down operational (OPEX) costs.

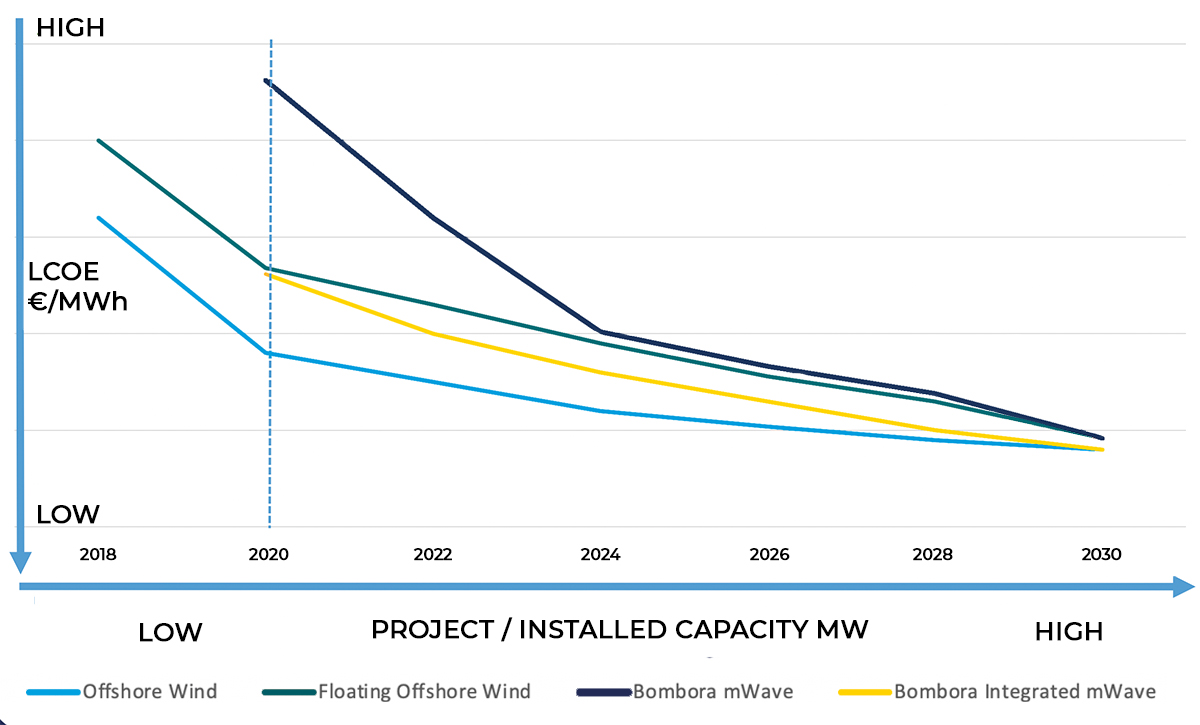

In 2016, Bombora completed a comprehensive study to investigate the Levelized Cost of Energy (LCOE) of a commercial mWave wave farm. The study was funded by an Australian Renewable Energy Agency (ARENA) grant and based on a proposed 60MW Bombora wave farm in Portugal. Specialist industry suppliers including Worley Parsons, Norwegian Geotechnical Institute and Trelleborg were engaged to provide technical details and costing information for the analysis. The study was independently reviewed by domain experts BMT-WBM.

The study concluded that the initial Bombora wave farm would require the support of a special renewable energy “feed in tariff” program to be fully commercial in the first instance. These special tariffs are currently available in various parts of Europe.

Importantly, the study demonstrated that with learning rates that are standard for the industry, the cost of energy from Bombora wave farms could quickly compete with other energy sources.